Ettore Bugatti came from a family of artists, though he was not himself formally trained as one. He apprenticed at a bicycle manufacturer and began making cars without any engineering education. There are many remarkable artistic details that resulted from this unconventional origin story.

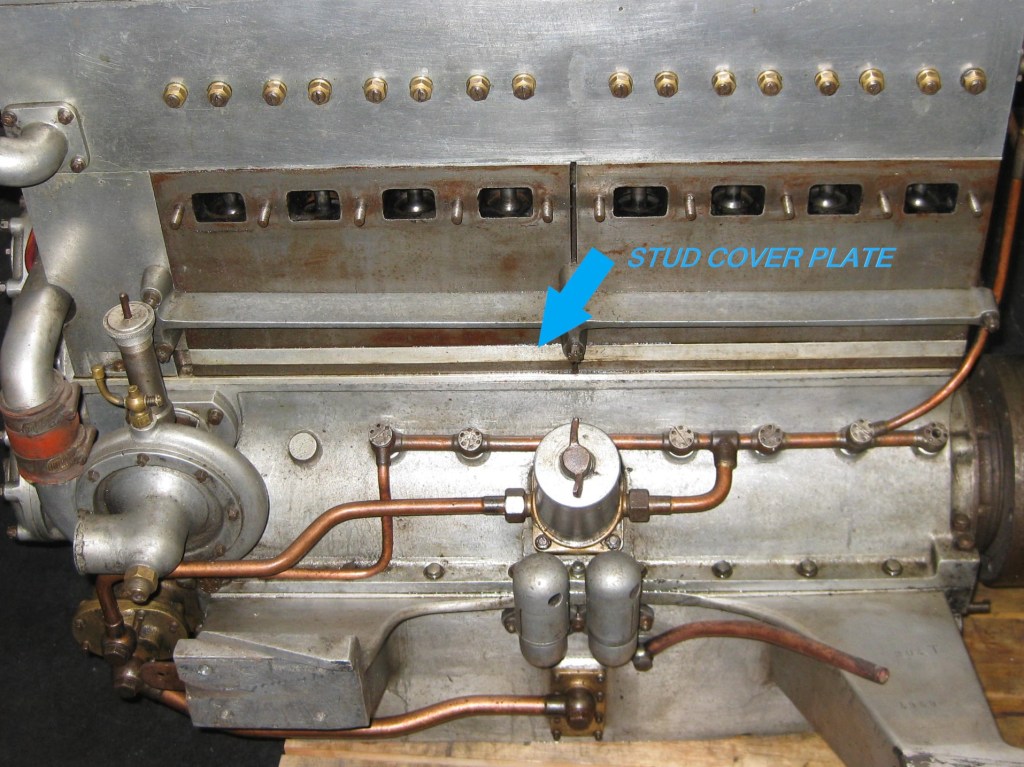

One example of Bugatti’s eye for detail are the lovely polished aluminum covers he manufactured to conceal the studs and nuts that hold the cylinder block to the crankcase on his Type 30 and 35 engines. Below is an example on an unrestored engine being prepared for a rebuild.

Isn’t that a lovely detail? The twenty 7mm studs that are hidden under the covers are sometimes a problem on engines that have lived a hard and fast life. They are known to crack and break, one by one, until a critical mass is reached and the remaining studs catastrophically all fail at once so that blocks are lifted off the motor by cylinder pressure, only retained by the cam drive tower at the front!

I haven’t personally seen this happen myself, but I’ve heard tales. Like a zipper it comes apart, they say.

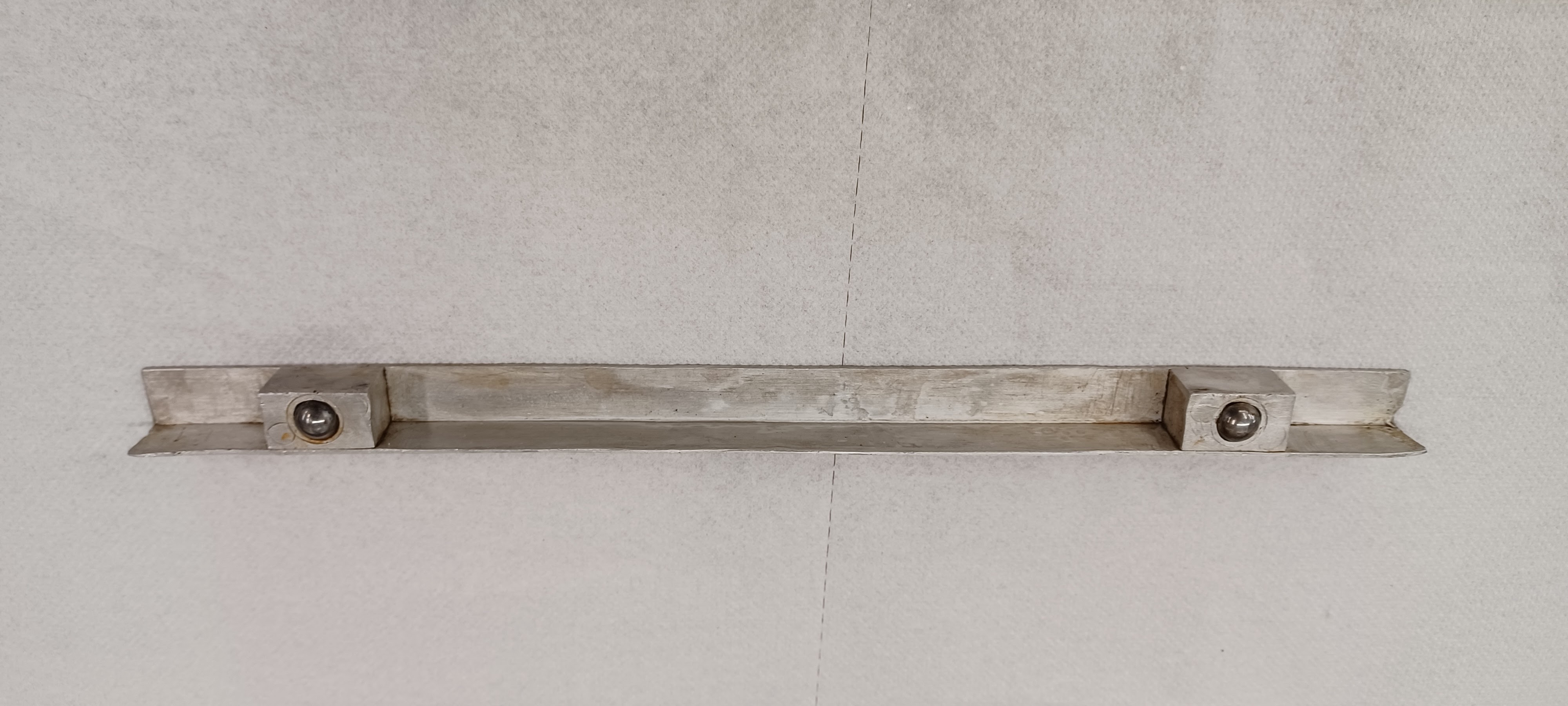

Of course, it’s a good idea to check these base nuts for tightness as part of a race prep or a thorough service, and here they are hidden away, no worries, mate. Though it’s fair to mention that they are essentially “quick release”, cleverly designed with sprung balls that click into a hole.

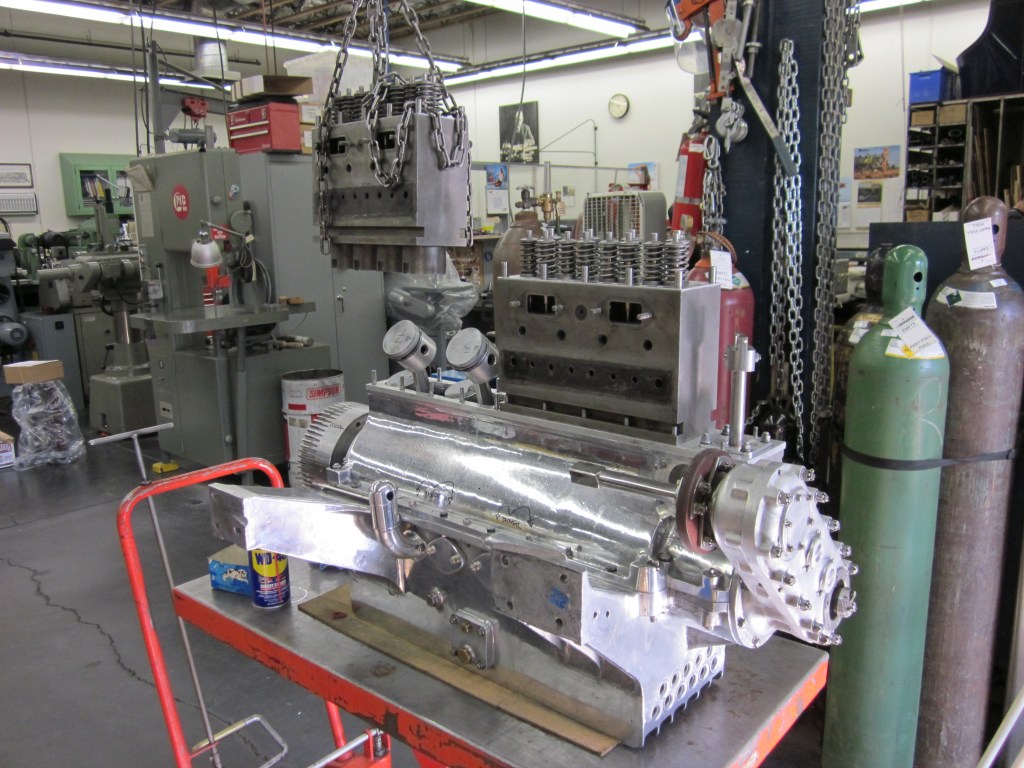

Here’s a look at one solution for when the studs are ruined and the threads have all been blown out of the aluminum… the holes in the case are all taken out to the next size with which you can achieve a complete thread in clean metal, and a new set of stepped studs is made.

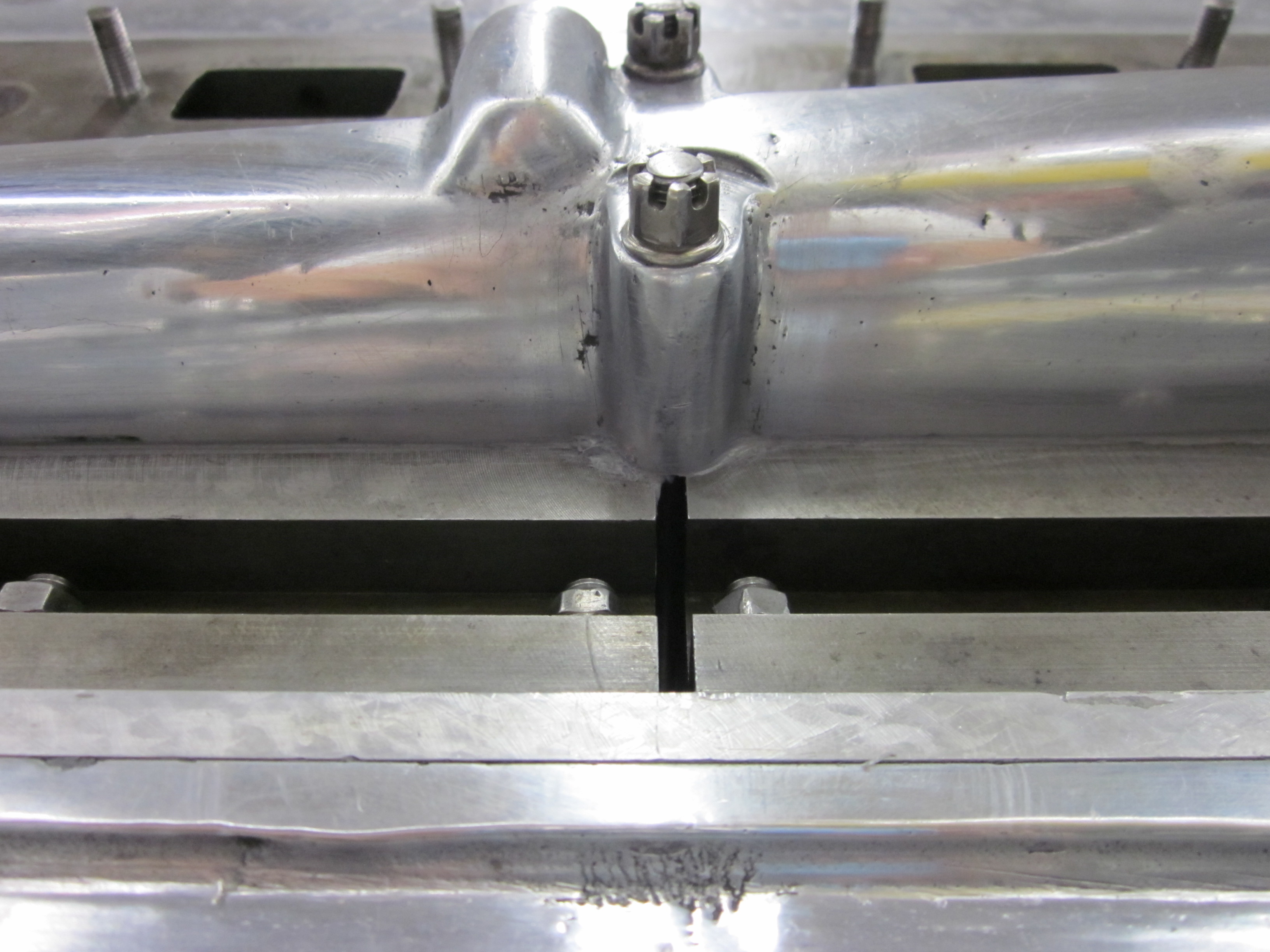

But the balderdash begins when you try to assemble the blocks onto the case. When the parts are mated and the blocks sit down under their own weight, the length of the studs prevents the mechanic from being able to fit the nuts onto the threads! They are too tall… so the drill is to fit the blocks over the pistons, getting all the piston rings up into the bores, then set the blocks down and rotate the engine a few times to make sure everything turns freely.

Then temporarily fit the cam box to align the blocks, lift the them back up, just enough to be able to get a finger in to clean the surfaces (don’t go too high or you may drop a piston ring out!), apply sealant, then slightly lower the blocks until a couple of threads of the studs appear… fit all the nuts down two threads, then lower the blocks a little more… turn the nuts some more… etc, etc… until the blocks are tight. Of course, you can’t use a socket or closed end wrench, because there is no room, so an open ended wrench turns one or two flats at a time. With all new studs and nuts it is a cinch to spin them down with your fingers, but on an assembly with used threads, there are invariably sticky nuts that hold up the show.

The later two valve motors mostly ditched the pretty nut covers, but they still made the stud length too long to leave room to easily fit the nuts. Fortunately they increased the stud diameter from 7 to 9 mm so that breaking the studs became less of an issue.

And finally, a look at what can be hidden with lovely polished aluminum covers. This next motor had a caretaker somewhere down the line that seemingly shortened the studs. Well, for whatever reason, they were so short that several nuts had only a few threads engaged. They were tight, and it ran well, so pulling the top end of the motor off just to fit new studs was out of the question.

I feel like Bugatti frequently made engineering sacrifices in reverence to the artistic aspect of the design. The height of this channel that the nuts live in could certainly been made taller to allow easier assembly, but that would have impacted the visual proportions of the element.

In the end, the marque’s reputation for beautiful engineering is well deserved, even if there are the occasional snags, here and there.

Do you have a favorite engineering detail from Bugatti, or other examples that stick with you? Let us know in the comments below…

Leave a comment